Why ANSI Standards Matter in PPE: Ensuring Worker Safety and Legal PPE Compliance?

Posted by Darman Distributors on Jul 4th 2025

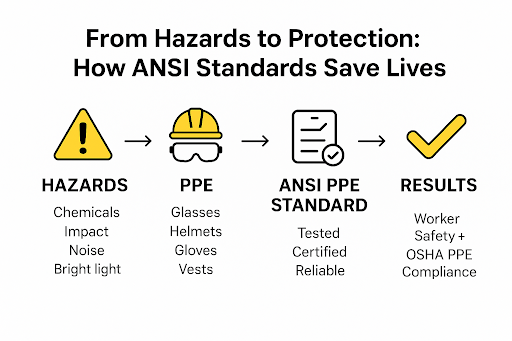

Being alert at work isn’t always enough to stay safe—you also need the right protective gear that actually works when it counts. Helmets, goggles, gloves, and other PPE are designed following ANSI PPE standards. Thanks to these rules, everyday safety gear becomes trusted tools that protect lives and keep businesses in compliance.

Knowing what these standards mean is important if you're picking out PPE, using it or handling it. These rules are more than just details, they are safety guides that help businesses meet OSHA PPE standards.

What Are ANSI Standards?

ANSI stands for the American National Standards Institute. It’s a non-profit organization that sets safety rules for PPE, construction materials, and many other products used every day.

When we talk about ANSI standards, we mean a set of tested and approved rules that tell manufacturers, and employers how protective equipment should be designed, and used. These rules:

- Are made by safety experts and reviewed by committees

- Are updated regularly to reflect new risks and technology

- Require strict testing to prove safety and performance

So, when a product says it meets an ANSI PPE standard, it means the gear has passed tough safety tests and can be trusted in the workplace.

Why ANSI Standards Matter in PPE?

The main purpose of PPE is to lower the risks that come from things like chemicals, moving objects, loud noises, and unsafe light. But not every gear is same. PPE can fail when workers need it the most if it is not certified equipment.

This is why ANSI standards for glasses, full head protection helmets, gloves, and more are so important. This is what they make sure PPE is:

- Reliable and consistent

- Legally compliant with OSHA PPE standards

- Able to reduce the chance of workplace injuries

? Example: If an employer hands out eyewear that doesn’t meet the ANSI standards glasses requirement, workers are at greater risk, and the company could also face legal action.

ANSI Standards Glasses: Protecting the Eyes

Safety glasses are one of the most common PPE items on any job site. The rule for them is ANSI Z87.1, which says what safety glasses should do to keep your eyes safe in different situations.

Glasses that meet this rule are tested for:

- Impact resistance

- Optical clarity

- Coverage against flying debris and chemicals

Certified glasses carry the mark “Z87” or “Z87+” on the lens or frame. To make sure their glasses meet the ANSI standards glasses rule, workers can quickly check this mark. This easy step makes things better for both workers and bosses.

Key ANSI PPE Standards

Here are some of the most common standards that guide protective equipment:

- Eye and Face Protection (ANSI Z87.1) — safety eye protection glasses and face shields

- Hearing Protection (ANSI S3.19) — earplugs and earmuffs

- Head Protection (ANSI Z89.1) — helmets, and hard hats

- High-Visibility Apparel (ANSI/ISEA 107) — reflective vests and jackets

- Hand Protection (ANSI/ISEA 105) — gloves tested for cut and puncture resistance

Meeting these ANSI PPE standards helps businesses stay compliant and workers stay safe.

Legal Benefits of Following ANSI and OSHA PPE Standards

Following ANSI rules doesn’t just improve safety—it also helps with compliance. OSHA often refers to ANSI standards when enforcing workplace safety. If an employer ignores them, they may face:

- Costly OSHA fines

- Legal claims and lawsuits

- Higher insurance premiums

On the other hand, when companies use certified gear, they show regulators and employees that they take PPE compliance seriously.

How Employers Can Support PPE Compliance?

Employers play a key role in maintaining workplace safety. Here are five steps to support PPE compliance:

- Choose certified gear – Only purchase PPE that meets the correct ANSI PPE standard

- Train workers – Teach staff how to check for ANSI markings (like Z87 on glasses)

- Inspect & replace regularly – Worn or damaged gear may no longer be compliant

- Stay updated – ANSI standards change, so review them often

- Keep records – Document purchases, inspections, and training

Risks of Ignoring ANSI PPE Standards

Failing to follow ANSI and OSHA rules can lead to serious problems. If PPE fails during use, it can result in injuries, fines, lawsuits, and a damaged reputation. Even if the gear “looks fine,” without ANSI certification it doesn’t count as proper protection.

The risks include:

- OSHA penalties

- Worker injuries and claims

- Lower morale among employees

All of this can be avoided by following ANSI PPE standards and investing in certified gear.

Building Safety Awareness Among Workers

Employers must provide compliant PPE, but workers should also know how to recognize the standards. For example, a worker who understands the ANSI standards glasses rule can quickly spot unsafe eyewear and prevent potential injuries.

When both employers and employees value PPE compliance, safety becomes part of the workplace culture—not just an added task.

Creating a Safer Workplace

At first, ANSI standards might seem complex, but they are practical tools designed to protect people. By choosing certified gear, staying updated on OSHA rules, and training staff, companies build a stronger, safer workplace.

The main goal of ANSI PPE standards is to keep businesses aligned with OSHA PPE standards and protect workers every day. That’s safety you can count on.

Not sure if your current PPE meets the latest ANSI standards? Please talk to our safety experts for help.